Character Options 5" Radio Controlled NSD Dalek Toy, "Dalek Sec"

...Add Working Dome Lights

A big thank-you to my brother-in-law for giving us this 5 inch Dr. Who RC (Radio / Remote Controlled) Dalek toy made by Character Options. It's an NSD (New Series Dalek) style, in black, making it "Dalek Sec".

It arrived in need of a little TLC, as the eye-stalk had been broken off - it was during this repair work that I noticed it would be quite easy to add white LEDs to the Dome Lights... Also sometimes called "head lights", "ears" etc..

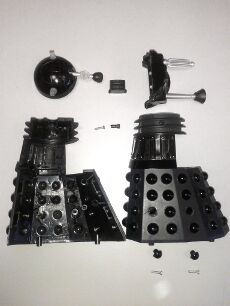

Dismantling The Dalek Toy

There are four screws securing the fender to the skirt. The fender also carries the electronic circuit boards, batteries and motors. These boards are half mounted by the main body (skirt and shoulders), so the fender can't be instantly removed due to wires holding it in place.

It took me a while to figure out how to take the rest of this dalek toy apart... It has screws hidden beneath two removable hemispheres in the skirt, and a screw under a (slightly more obvious) plug in the neck-bin area.

Once these screws are out, it's a case of gently prising the sides apart. The front of the shoulders / gun box, neck front insert, and dome will just drop out as it comes apart (as will the electronics and fender too).

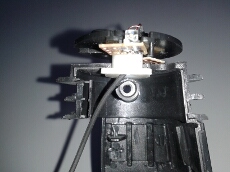

Once it's all apart, there are four screws holding the dome together, the inner plate holds the dome lights and eye-stalk pivot in place. You can see the broken eye-stalk above.

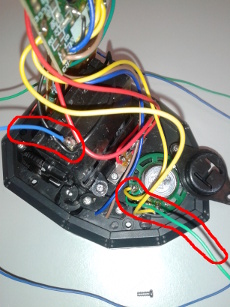

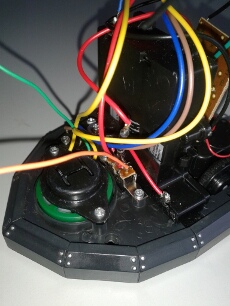

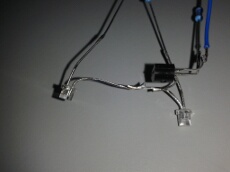

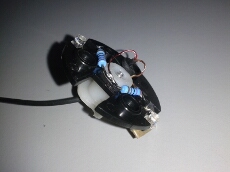

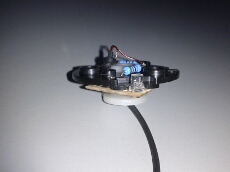

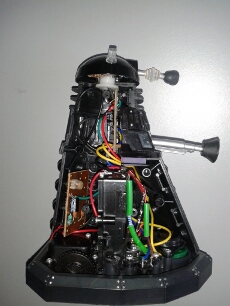

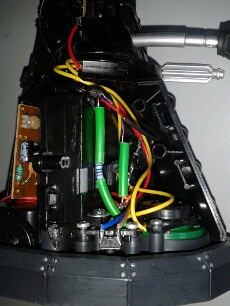

These images show the fender assembly and all circuitry.

Understanding The Dalek's Operation

After a little prodding around with a beautiful old AVO (oldschool Avometer 8 Mk5), I found a suitable signal to operate the LED's - from the main circuit board's audio output to the speaker.

As the toy has just one +ve power supply of 4.5Vdc, the speaker is driven by a "full bridge Class D" amplifier, which works in the following way:

The amplifier places both sides of the speaker at +2Vdc (with refrence to 0V / Battery -ve, about half the power supply voltage), then uses simultaneous +ve and -ve pulses (with refrence to +2V) to pull the speaker in either direction (achieving full speaker cone excursion), this is achieved by having one of the output lines do exactly the opposite of the other. So when one is pulled to 0V, the other is pulled to +4V and vice versa. The speaker will rest when both wires are set to +2V.

Note: a modern multimeter is next to useless when trying to measure such signals (DC and high frequency AC combined)... think sampling rate..

When there is a pause in-between audio, the speaker sits with +2V on both terminals, so no voltage across the speaker. After the audio is finished, this +2V drops down to 0V (saving battery power).

So this +2V is really convenient to pick up a signal to operate the LED's! They won't flash in sync with the audio, but will stay on while audio is being produced, which is good enough for a toy!

I had ideas on using a dc-decoupled (capacitors) comparator (op-amp) to flash the LED's in sync with the audio, but this method is much simpler / quicker to achieve.

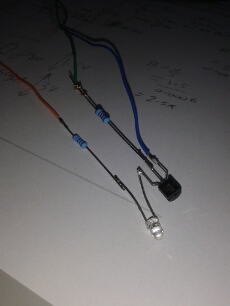

Above: the first two images show the yellow speaker wires; the right-hand image shows the wires that I soldered to the battery -ve terminal (blue) and one of the speaker terminals (green), it doesn't matter which speaker terminal you use.

Simple Circuit Design - KISS

KISS - Keep It Simple, Stupid!

I'm using a small transistor to drive the LEDs. These super efficient white bright LEDs from Maplin (SKU: N21FN) draw roughly 1mA each, but need about 2.6V across them to light up [please note the MISTAKES on their website regarding the LED specs - I blew up three of these LED's driving them hard at 3.5V! But Maplin sent me replacements free of charge].

I'm sure the audio output wouldn't mind a couple of extra milliamps of load to drive the LED's, however, the voltage (2V) would not have been enough to turn the LED's on, so the transistor was used to offer them more voltage from the battery. The other benefit of using the transistor is that the additional load on the audio output s further reduced.

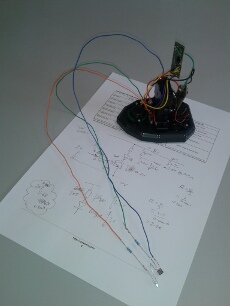

Testing The Prototype Circuit

The test circuit is based on a 2N5551 Transistor (Q1).

Above: The full Dalek Sec dome-light LED circuit diagram, showing all components of the finished circuit. Download the Fritzing .fzz circuit diagram file HERE (Right click, save-as...).

I'm using a 10KΩ resistor (R3) in series with the Base leg, to limit the Base current to 1µA. The DC component of the speaker Voltage is 2V, the Base-Emitter voltage of the transistor is 1V (@ 1µA, from the datasheet), so the other 1V is dropped across the resistor (R3).

The LED's series resistor of 2K7Ω (R1 and R2) is to limit the LED current to around 1mA. The LED forward voltage is around 2.5V, leaving about 2V across the resistor. The power consumed by each LED is only 2mW, so tiny resistors (in terms of power rating / Wattage) would do the job. My 0.6W resistors are a tad overkill.

This additional orange wire is connected to the load side of the power switch at 4.5Vdc, then off to the LED series resistor.

BLIMEY!!! The circuit actually worked brilliantly first time!

As hoped, the LED illuminated solidly during speech, and went off afterward... Perfect!

See the video here:

Ok, so it worked with one LED, now for both... but before I tested with both LEDs, I looked a the physical installation side..

Installation Of The LEDs

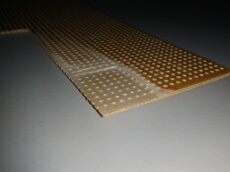

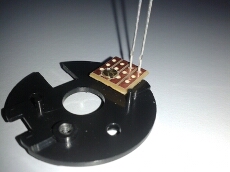

The dome light clear plastic mouldings have recesses in their bottoms, where the 3mm LEDs can fit quite nicely with some room to spare. There is also a boss moulded into the plastic dome insert, which looks like it could take a screw... so I decided to mount the LEDs on two small pieces of Veroboard (Stripboard), screwed into place via the bosses.

However, there is very little space between the dome insert and the top of the neck bin, so I had to file down the thickness of the Veroboard to approx 50% to gain enough room for the LED soldered joints!

Looking at how the veroboard will be mounted, the LEDs were a touch too long for the recess of the dome light moulding, so I filed the ends off the LEDs to shorten them a bit.

I then lashed up a quick test circuit for both LEDs, operating from one transistor... but constructed it so that I could test how the dome lights would look illuminated to confirm my plan would work.

And here's the video:

I found a couple of brass M2 countersunk screws at home, in my "You never know when this could be handy" stock. They fitted the dome insert bosses perfectly. I drilled and countersunk the Veroboard, then had a trial fit.

There was just enough clearance between the veroboard and the neck bin to allow for soldered joints. The image above right shows a small plastic peg which is a good guide for the height of the neck bin.

So then it was time to solder the LEDs in place!

The finished job looks a bit asymmetrical, this is just due to the loations of the screw bosses.

Dalek Eye Stalk Repair

The eye stalk was repaired by drilling out the broken part of the old stem, and inserting what was left of the eye stalk into the pivot. This resulted in a slightly shorter eye stalk, but hey, it's a toy!

NOTE:Don't glue the stalk into the pivot yet! It must be inserted through the dome first!

I'll keep the stalk as a push-fit for now, as glueing it in place will be the last job after the re-assembly is completed.

Dome Rotation Modification

It's a shame that this Character Options Dalek Sec's dome doesn't turn.. It's fixed pointing straight forward. I think this is probably how the eye stalk got snapped off in the first place, by a kid believing the dome should rotate!

So, I thought I'd fix that while I was at it!

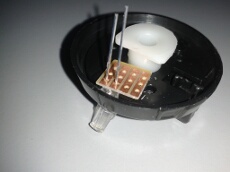

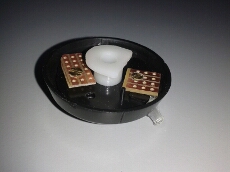

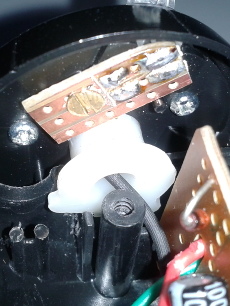

The white plastic central pivot isn't much of a pivot, however with a little tweak, it can be!

It's "D" shape is intended to collide with two plastic ribs inside the Dalek neck, one stops it from turning left, the other from turning right.

My fix for this was to modify the "D" shape and also the two plastic ribs within the neck. I retained some limitation of movement, as it'll save my internal wires (for dome lights) from getting trashed, but it resulted in over 180° of motion.

so, I filed down the ribs with the edge of a needle file, and also rouded off the "D" shape, but left two "hook" shapes to limit it from going all the way round by hooking onto the modified ribs, as can be seen below.

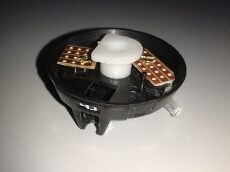

Wiring Up The Dome

I used a piece of old headphones wire to connect the dome to the dalek body, as it's designed to be very flexible without breaking down. A small hole was drilled through the pivot at an angle to bring the wire out in the upper part of the dome.

The resistors are mounted in the upper part of the dome by drilling through the veroboard and plastic dome insert for the legs to pass through, then soldered to the veroboard.

I cut some of the plastic away from a pillar to give the wire a little more space to move, saving strain. Then I gave the new Dalek dome assembly a little test to check I'd wired it correctly:

There was just enough space for the wire, but cuting away some of the pillar gave it a little more room.

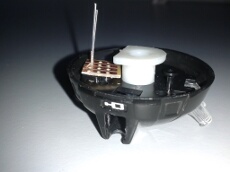

Mounting The Transistor

I simply mounted the transistor by soldering the Emitter to the battery -ve terminal, then the Base resistor was soldered directly to the speaker terminal.

The resistor legs felt a bit too exposed, so I found some (not ideal, but all I could find quickly) sleeving for them.

Final Wiring

While not ideal diamter, or shrinkable, I found some sleeving (green) for the Base resistor legs, and the LED +ve connection.

Re-Assembly

Rebuilding the dalek is just the reverse of the dismantling. Start with the left hand side casing, as it holds the circuit boards.

Make sure no wires are going to foul any of teh plasticwork, avoid wires getting trapped.

Insert the front of the shoulders (with the exterminator and plunger arm), then insert the small front of the neck section above the shoulder section.

The left hand side casing can then be eased back into place, then once snugly together, pushed down onto the fender / base.

Once all screws are back in place, glue the two hemispheres and the neck plug back in place.

Dalek dome rotation and flashing dome lights finished!

Dalek Job Done!

Final video of the finished project, trundling, making Dalek speech noises with lights flashing!

Thanks for reading, Scott.